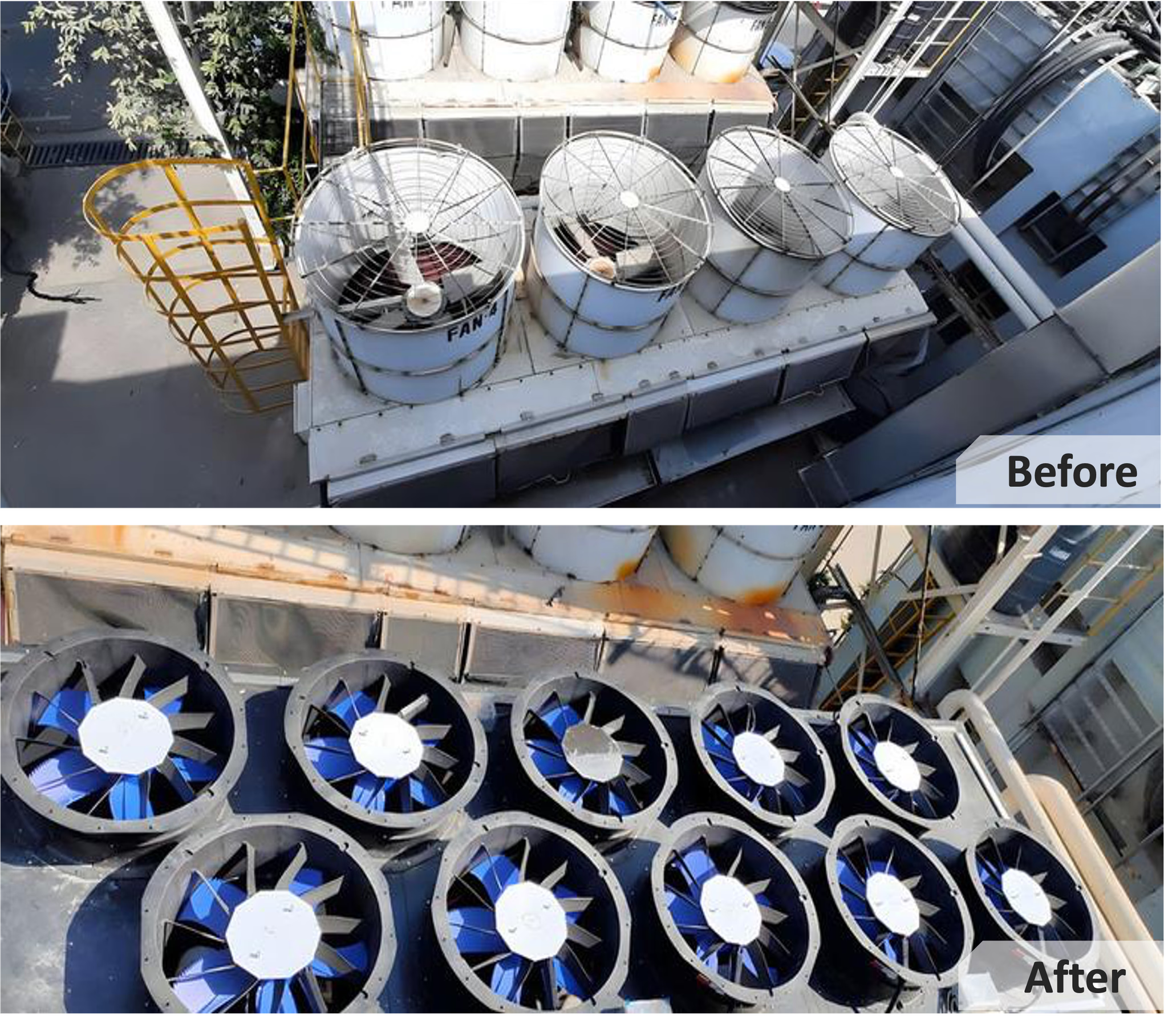

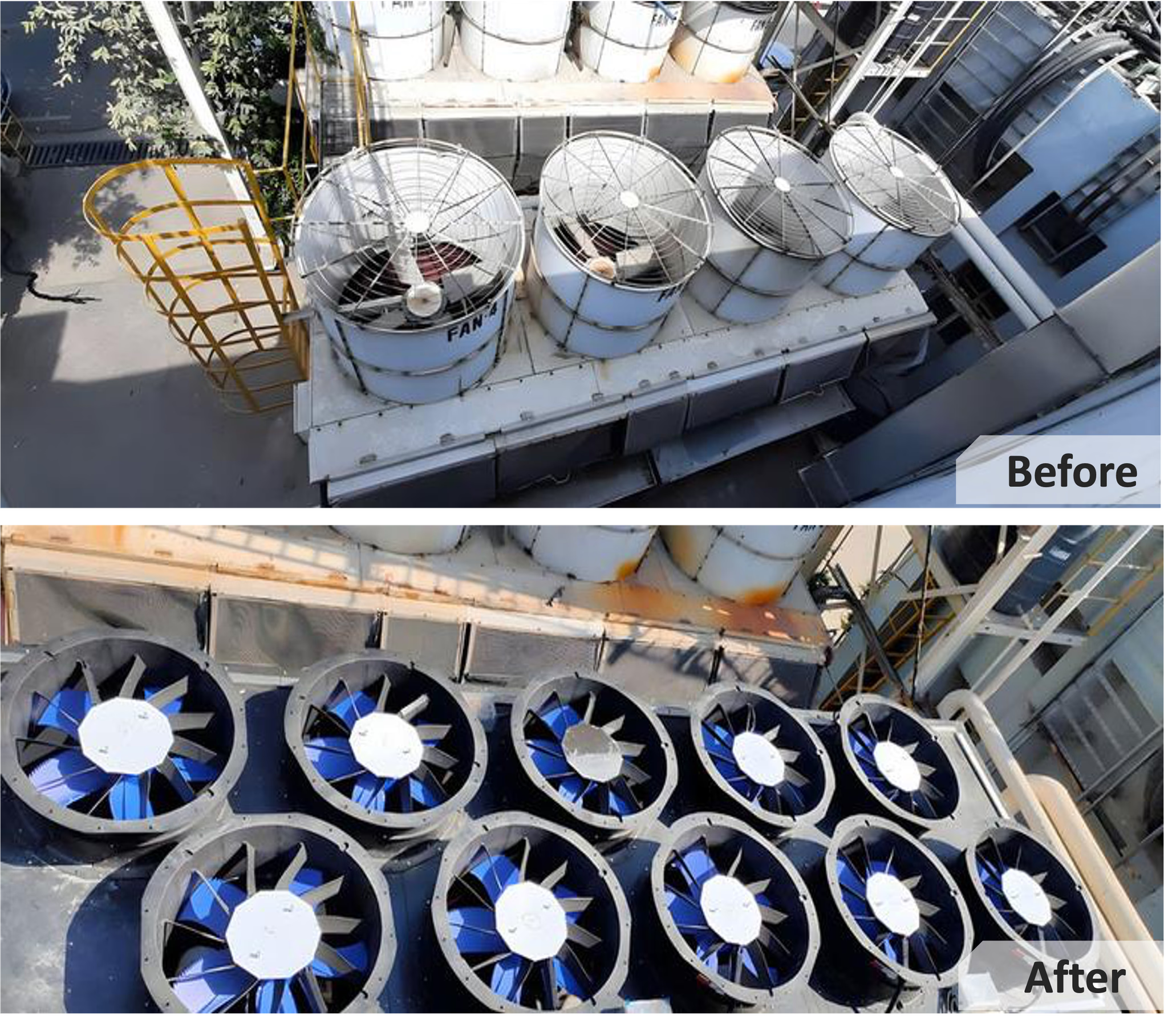

At Aad Tech, we provide advanced Cooling Tower EC Fan Retrofit Solutions designed to replace conventional single large fan systems with high-efficiency EC axial fans and smart controllers. Our retrofits are engineered to deliver maximum cooling tower efficiency, reduce energy consumption, and extend equipment life, all while ensuring seamless integration with modern building systems.

When compared to traditional variable frequency drive (VFD) systems, EC Fan Retrofits offer additional energy savings and superior performance in cooling tower applications, making them the smarter choice for energy-efficient upgrades. One of the key benefits of EC technology is its ability to improve energy savings in cooling tower operations, helping facilities significantly cut down on power consumption and operational costs.

This upgrade not only improves cooling performance but also enhances system reliability, delivering up to 40–50% energy savings. It’s one of the most effective and sustainable ways to optimise cooling tower efficiency for industries looking at quick payback and long-term savings.

We provide Cooling Tower EC Fan Retrofit Solutions that replace conventional single large fan systems with high-efficiency EC fans integrated with smart controllers. This retrofit not only optimizes cooling tower performance but also delivers energy savings of up to 40–50%, making it one of the most effective upgrades for sustainable operations.

Our solution uses multiple smaller EC axial fans instead of a single large fan, ensuring optimized airflow distribution through the tower. This modular design offers inherent redundancy, so the system continues running reliably even if one fan is offline. Despite the compact fan arrays, efficiency is never compromised—our design can reduce the system size by up to 40–45% without any loss of performance.

At the core of the retrofit is our Smart Controller, equipped with a precise algorithm that continuously analyzes real-time data and modulates fan operation to match actual cooling demand. The system is capable of operating in BMS, Auto, or Manual modes and supports multiple communication protocols such as Modbus, ensuring seamless integration with Building Management Systems (BMS).

By combining high-efficiency fans, intelligent controls, and modular redundancy, our Cooling Tower EC Fan Retrofit provides a robust, reliable, and future-ready solution. The result is lower energy consumption, reduced OPEX, and higher system uptime, making it an ideal choice for industries looking to maximize performance while minimizing costs.

The retrofit of the cooling tower using the Aad Tech system optimises the system efficiency reducing energy consumption up to 50%. We replace the existing fan with an EC drive & smart controller system. Our smart controller has a built-in highly precise complex algorithm which analyses the realtime dataset, processes that and modulates the fan system accordingly.

A High Efficiency fan is used to reduce the power consumption

Multiple small fans are the solution for optimized flow of air

The Aad Tech Axial fan system can reduce the size of the system up to 40-45% without losing efficiency

The system supports various communication protocols such as Modbus, etc. for BMS

That system can be operated on various modes respectively BMS/AUTO/MANUAL

The retrofit of the cooling tower with the Aad Tech system. It optimises the system efficiency and energy consumption is reduced by up to 40-50%. We replaced the existing fan with an EC drive & Smart controller system. Our smart controller has inbuilt a highly precise complex algorithm which analyses the realtime dataset then processes that and modulates the fan system accordingly.

A High Efficiency fan is used to reduce the power consumption.

Multiple numbers of small fans is the solution for optimized flow of air through

Aad Tech Axial fan system can reduce the size of the system up to 40-45% without losing any efficiency.

The system supports various communication protocols such as modbus, etc for BMS.

The redundancy in the system increases reliability of the system.

That system can be operated on various modes respectively BMS/AUTO/MANUAL.

A cooling tower is a heat rejection device in HVAC and industrial systems that removes excess heat from circulating water through evaporation. The fan plays a critical role - it accelerates airflow, expels warm, moist air, and draws in cooler air to maintain optimal water temperatures for efficient heat exchange. Without efficient fans, cooling performance drops, energy use rises, and system reliability suffers. Aad Tech’s EC axial fan systems, paired with smart controllers, ensure consistent airflow, modular redundancy, and precise demand-based operation. This results in lower power consumption, improved cooling efficiency, and longer equipment life, making Aad Tech retrofits a future-ready solution for modern industries.

Significantly reduce power consumption and OPEX with high-efficiency fans.

Multiple small axial fans ensure optimised cooling performance.

Modular design provides built-in redundancy, so operations continue even if one fan is offline. Ask About Modular Fan Retrofits – Book a consultation to understand how multi-fan EC systems keep you running without downtime.

Book a consultation to understand how multi-fan EC systems keep you running without downtime.

Retrofit can reduce the system size by 40–45% without compromising efficiency.

Aad Tech’s EC axial fans, designed for cooling towers, operate with aerodynamic efficiency and dynamically balanced rotors to reduce vibration and noise compared to conventional fans. Learn more on our Axial Fans page

Smart controller supports Modbus and integrates with Building Management Systems (BMS).

With Aad Tech’s Smart Controller, cooling tower fans continuously analyse real-time data and adjust speed to match demand. This delivers high efficiency even at partial loads, ensuring consistent savings across different operating conditions.

Automation ensures consistent performance and long-term savings.