Ice buildup, erratic temperatures, and sky-high electricity bills are the silent killers of cold storage profitability. When moisture levels peak, standard ventilation systems often buckle under the pressure. The solution isn’t just “more power,” it is smarter engineering.

The Moisture Trap in Cold Chain Logistics

In high-humidity zones, standard AC motors face a relentless enemy: condensation. The reason is that the motor housing’s temperature often drops below the ambient air’s dew point. Moisture seeps into the motor windings, leading to short circuits, insulation breakdown, and frequent downtime.

A specialised humidity fan becomes essential here. Unlike traditional units, these are designed with sealed electronics and conformal-coated circuit boards to thrive where others fail. Proper moisture management ensures that electrical components remain dry even when the external environment is saturated.

Why the Electronically Commutated Fan Changes the Game

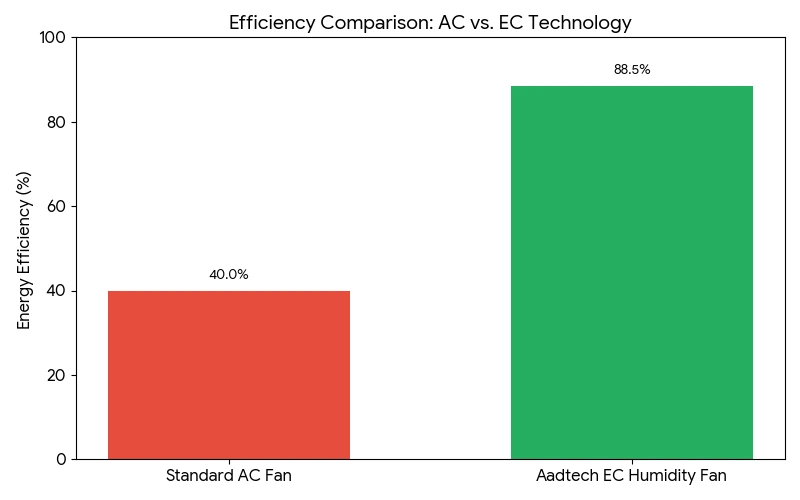

Traditional fans run at a single speed, regardless of the actual cooling demand. Such an “all or nothing” approach is incredibly wasteful. An electronically commutated fan (EC fan) uses integrated electronics to adjust its speed in response to real-time needs.

Air Density Management

Cold air is denser and harder to move than warm air. As temperatures drop, the mass of the air increases, which increases the torque requirements on the motor. The EC fan HVAC systems use onboard intelligence to maintain constant airflow even as air density fluctuates. Such precision prevents the motor from overheating or “hunting” for the correct RPM, ensuring stable temperatures across the entire storage facility.

Heat Reduction and Thermal Load

Standard motors generate significant internal heat due to friction and electrical resistance. In a refrigerated space, this is a double-sided cost: you pay for the electricity to run the fan, and then you pay again for the refrigeration system to remove the heat the fan created. An EC centrifugal fan stays cool, significantly reducing the internal heat load your refrigeration system must remove.

Read this blog to understand what an EC motor is and why it’s increasingly preferred over traditional motors.

Engineering for Extreme Conditions

At Aadtech, the focus is on transforming industrial efficiency through precise engineering. In environments where temperatures plummet, equipment faces unique mechanical strains that go beyond simple cooling:

- Grease Thickening: Standard bearings often seize as lubricants harden in the cold. It increases friction and can lead to motor burnout. EC motors use specialised low-temperature lubricants to maintain smooth rotation.

- Moisture Ingress: High-humidity zones cause condensation within the motor housing during off-cycles. Specialised humidity fan designs include “weep holes” or breathable membranes to allow moisture to escape without letting water in.

- Energy Waste: Standard fans cannot adapt to the fluctuating thermal loads of a busy warehouse where doors are constantly opening and closing.

By upgrading to an EC fan, facilities see an energy consumption drop of up to 65% in optimal retrofits. This aligns with a broader vision of sustainable engineering where every kilowatt saved contributes to a greener planet.

Avoiding the “Ice-Up” Disaster

A common pain point in cold storage is the defrost cycle. When fans run at full tilt during defrost, they scatter heat throughout the room. The surface ice melts on the evaporator, but that moisture often refreezes on the produce or the ceiling, creating dangerous “ice stalactites.”

Using a smart humidity fan allows for ultra-low speed operation during these cycles. The advantage is that it keeps the heat exactly where it is needed on the coils rather than blowing it into the refrigerated space. This precision prevents product spoilage and maintains the integrity of the cold chain.

To understand how these components fit into your broader climate strategy, see our guide on why AHU fans are indispensable for HVAC systems.

The “Extreme Environment” Upgrade Checklist

Before committing to a new ventilation setup, ensure your selection meets these four critical criteria for long-term reliability:

1. True IP Rating

Check the Ingress Protection (IP) rating. For cold storage, an IP55 or IP67 rating is non-negotiable. The process protects the electronically commutated fan against dust and, more importantly, low-pressure water jets and heavy condensation.

2. Integrated Controller

Can the fan communicate with your Building Management System (BMS)? Modern EC fan HVAC units feature Modbus or 0-10V control inputs. This allows the system to automate speed based on humidity sensors, reducing the human error factor in climate control.

3. Corrosion Resistance

Are the fan blades made of composite materials or high-grade aluminium? In 90% plus humidity, steel components rust quickly. Composite materials withstand moisture and are lighter, further reducing the energy needed for startup.

4. Soft-Start Capability

Traditional motors draw a massive “inrush” current when they start. In cold air, this draw is even higher. EC technology features “soft-start” programming that gradually ramps up speed. It works to prevent power surges and extends the life of your electrical breakers.

The Hidden Cost of Maintenance

In a high-humidity facility, maintenance is often the largest hidden expense. Accessing fans in a cold room requires specialised gear, safety protocols, and often involves shutting down a section of the warehouse.

Because an EC fan lacks brushes and operates with less friction, its maintenance interval is significantly longer than that of an AC equivalent. When you choose a high-quality humidity fan, you are not just buying a motor; you are buying hours of uptime and reducing the physical risk to your maintenance team.

Calculate Your Payback Period

At Aadtech, we do not just promise savings; we quantify them. Most cold storage facilities see a “break-even” on their investment within 12 to 18 months through reduced maintenance and electricity costs.

To see the exact numbers for your facility, use our Fan Savings Calculator. Simply input your current motor wattage and run hours to see the immediate impact on your bottom line.

Strategic Retrofitting: The Path to Net Zero

Retrofitting is the most cost-effective way to modernise an ageing facility. Instead of replacing an entire Air Handling Unit (AHU), replacing the fan array with EC centrifugal fan technology can provide a 40% improvement in system efficiency overnight. This modular approach allows for staged upgrades, ensuring that operations are never fully halted.

By focusing on these “micro-efficiencies,” companies can meet aggressive ESG (Environmental, Social, and Governance) targets without the capital expenditure of a new build. It is about making the equipment you already own work harder and smarter.

Conclusion

The transition to high-performance ventilation is a practical step toward operational excellence. Investing in a robust humidity fan ensures that moisture remains a managed variable rather than a mechanical threat.

By choosing Aadtech’s bespoke solutions, you are not just buying hardware; you are adopting a strategy that slashes OPEX and supports global net-zero goals. Our engineering team specialises in identifying the specific pressure drops and thermal challenges of your unique site to provide a tailor-made solution.

Frequently Asked Questions

Standard motors fail in humid conditions due to internal condensation. Aadtech EC fans are humidity-engineered with IP55/IP67 protection, coated electronics, and drainage systems to stay dry.

In cold conditions, thickened grease raises startup torque and risks motor failure. EC fans solve this with low-temperature lubricants and soft-start electronics that prevent fuse blows and drive damage.

EC fan HVAC retrofits are modular. Old belt-driven AC fans can be replaced with EC fan walls or individual units that fit existing AHUs, delivering efficiency and speed control without major infrastructure changes.

While EC fans cost more initially, cold storage applications see ~65% energy savings and near-zero maintenance, delivering a 12–18 month payback and lower lifetime cost than AC motors.

During defrost, standard fans push heat into the room, causing moisture to refreeze on products. Smart humidity fans run at 5–10% speed, concentrating heat on coils to melt ice while protecting stored goods.