Choosing AHU refurbishment over replacement is the most brilliant move when the unit’s structural steel casing remains sound, but internal components like fans, coils, or insulation show signs of age. If your building requires improved air quality and lower energy bills without the massive capital outlay of a new install, restoring your existing system often yields a higher return on investment.

The Financial Logic of Restoring Over Replacing

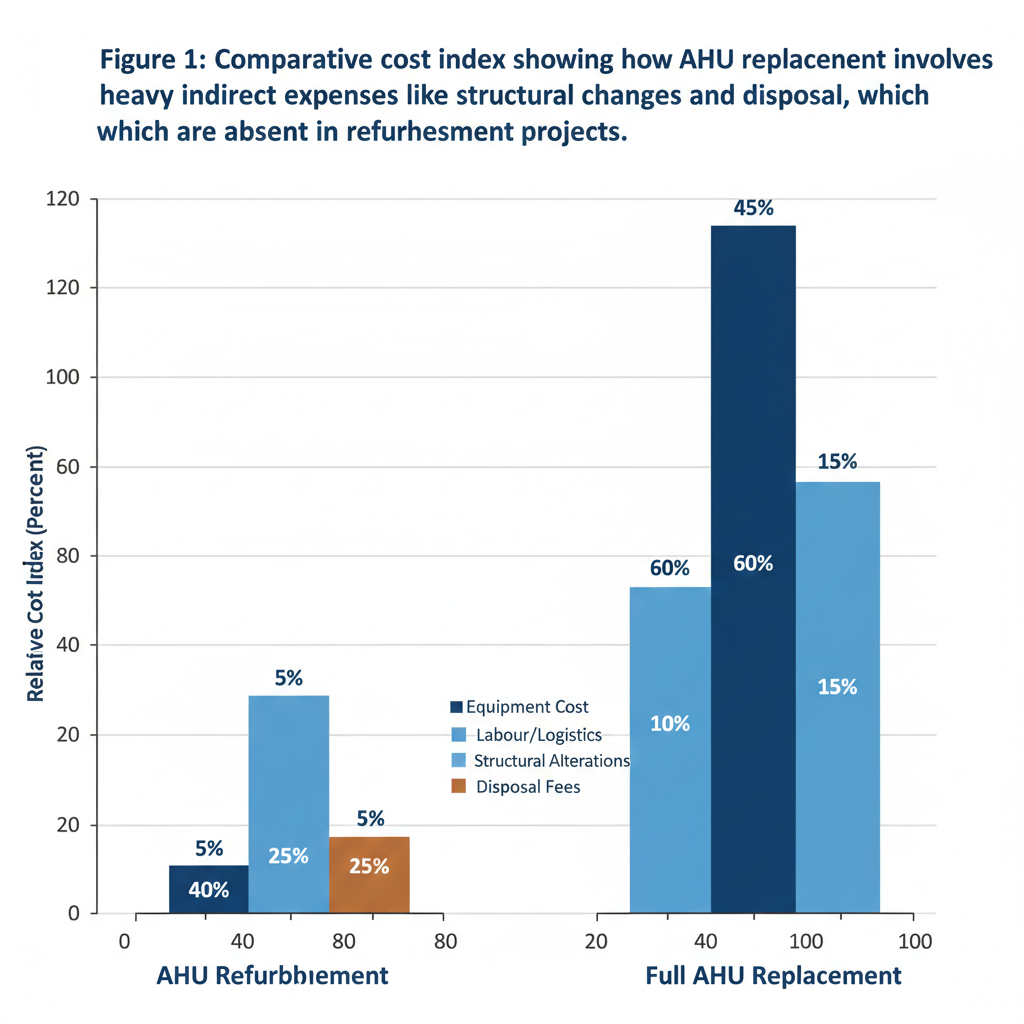

Building managers often face a dilemma when air handling units cross the fifteen-year mark. A complete AHU replacement involves more than just buying a new machine; it requires structural changes, crane hires, and significant downtime. Refurbishing the unit typically costs only 35% to 50% of the cost of a new purchase. This price gap allows facilities to redirect funds toward other critical infrastructure needs.

According to the CIBSE Indicative Economic Life Expectancy Tool, while the mechanical parts of an air handler typically reach their economic limit at twenty years, the structural framework often remains robust far beyond this period, providing a solid foundation for restoration. Tossing away a perfectly functional chassis because a motor failed is an environmental and financial waste. By focusing on internal mechanical upgrades, you bypass the logistical nightmare of dismantling roof sections or walls to fit a new unit inside.

Visualising the Value: Refurbishment vs. New Installation

Understanding where your money goes helps in making a definitive choice. The following chart compares the typical cost allocation between these two paths.

Strategic Comparison: The Decision Matrix

| Feature | AHU Refurbishment | Full AHU Replacement |

| Capital Expenditure | Typically 35% – 50% of new equipment costs. | High upfront cost plus significant logistical expenses. |

| Project Timeline | Rapid execution; often completed in days. | Extended lead times for manufacturing and site work. |

| Building Disruption | Minimal; units stay in-situ with no demolition. | High; requires crane hires or wall openings. |

| Operational Continuity | Phased works allow for maintained airflow. | Total system shutdown required during swap-over. |

| Energy Performance | “Zero-hour” reset using modern EC fans. | Peak efficiency, but limited by old ductwork. |

| Sustainability | Low embodied carbon; prevents landfill waste. | High footprint due to new manufacturing. |

Signs Your System Needs a Lifeline

Mechanical fatigue manifests in several ways. High energy bills often point to inefficient, belt-driven fans that slip and waste power. Visible corrosion on condensate trays or damp internal insulation can lead to mould growth, compromising indoor air quality. If your current unit struggles to maintain set temperatures despite constant repairs, it signals that the heat transfer coils are fouled beyond basic cleaning.

Standard AHU replacement becomes necessary only if the outer casing has rusted through or if the building’s load requirements have changed so drastically that the original footprint cannot cope. For most other scenarios, swapping old parts for modern equivalents solves the problem.

Engineering Excellence: The AadTech Advantage

As a premier leader in energy solutions and a top-tier AHU manufacturer, AadTech bridges the gap between old hardware and future-proof performance. We don’t just fix parts; we re-engineer airflow. Our team integrates high-efficiency EC fans and advanced filtration into your existing frames. This approach transforms a legacy machine into a high-performance asset that meets modern BREEAM standards. Our deep manufacturing roots mean we understand the “bones” of an air handler better than anyone else, ensuring every restoration aligns with original factory tolerances.

Improving Energy Efficiency Through Component Upgrades

Old air handlers usually rely on AC motors with pulleys and belts. These systems lose significant energy through friction and heat. Replacing them with direct-drive EC (Electronically Commutated) fans can reduce fan energy consumption by up to 70%. These fans also provide better control, allowing the system to ramp up or down in response to actual demand.

Upgrading the cooling and heating coils also plays a vital role. Modern coils feature improved fin designs that maximise surface area contact. This change ensures the system reaches desired temperatures faster, putting less strain on the chillers and boilers connected to the unit.

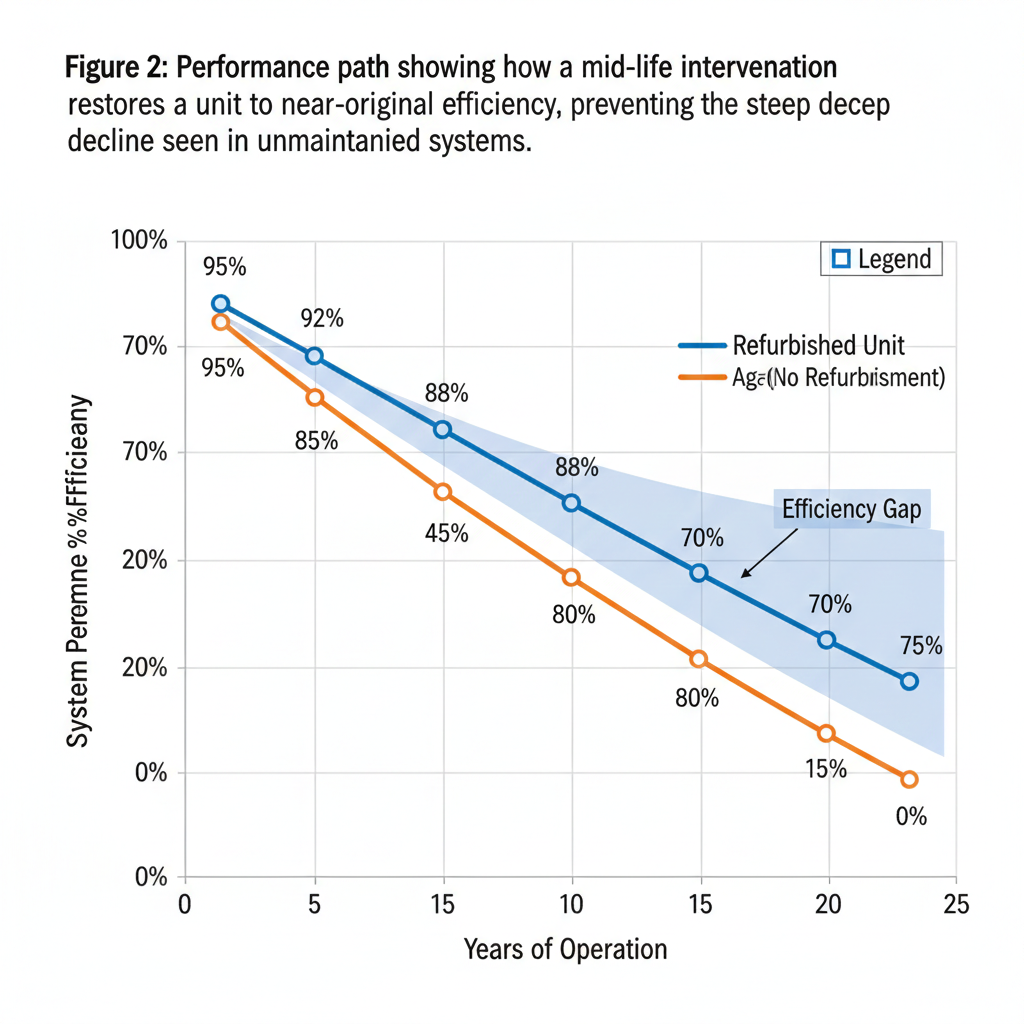

Comparing Life Cycles: A Long-Term View

A common myth suggests that new units last longer. In reality, a professionally refurbished unit receives a “zero-hour” reset. By replacing all moving parts and treating the casing with anti-corrosion coatings, the unit gains an additional 15 to 20 years of service life.

Minimising Building Disruption

A complete AHU replacement often requires shutting down entire floors for weeks. Refurbishment happens in stages. Technicians can work during night shifts or weekends, replacing one component at a time. This modular approach ensures the building stays occupied and functional, which is vital for hospitals, data centres, and busy office blocks.

Making the Final Decision

Evaluate your unit based on three pillars: structural integrity, access difficulty, and budget. If the box is solid but the guts are failing, restoration is the winner. This path provides a greener, cheaper, and faster way to achieve peak HVAC performance.

Explore our latest energy-saving insights to see how modern engineering breathes new life into old infrastructure.

Every successful facility management plan relies on high-quality air. Investing in AHU refurbishment ensures your occupants stay comfortable while your overheads stay low. Partner with a manufacturer that understands the science of air to guarantee your building’s future.

Frequently Asked Questions

Refurbishment usually takes a few days and occurs in phases, whereas replacement can take weeks due to structural work and complex logistics.

Yes. By upgrading to EC fans and improving heat transfer, you reduce operational carbon emissions. Reusing the metal casing also reduces embodied carbon.

While the casing remains, all new components installed during the process come with full manufacturer warranties, providing peace of mind.

The fan assembly is the most frequent upgrade. Switching to modern EC plug fans offers the fastest return on investment through energy savings.

If there is deep structural pitting, holes in the main frame, or significant warping of the panels that prevents an airtight seal, a replacement is necessary.