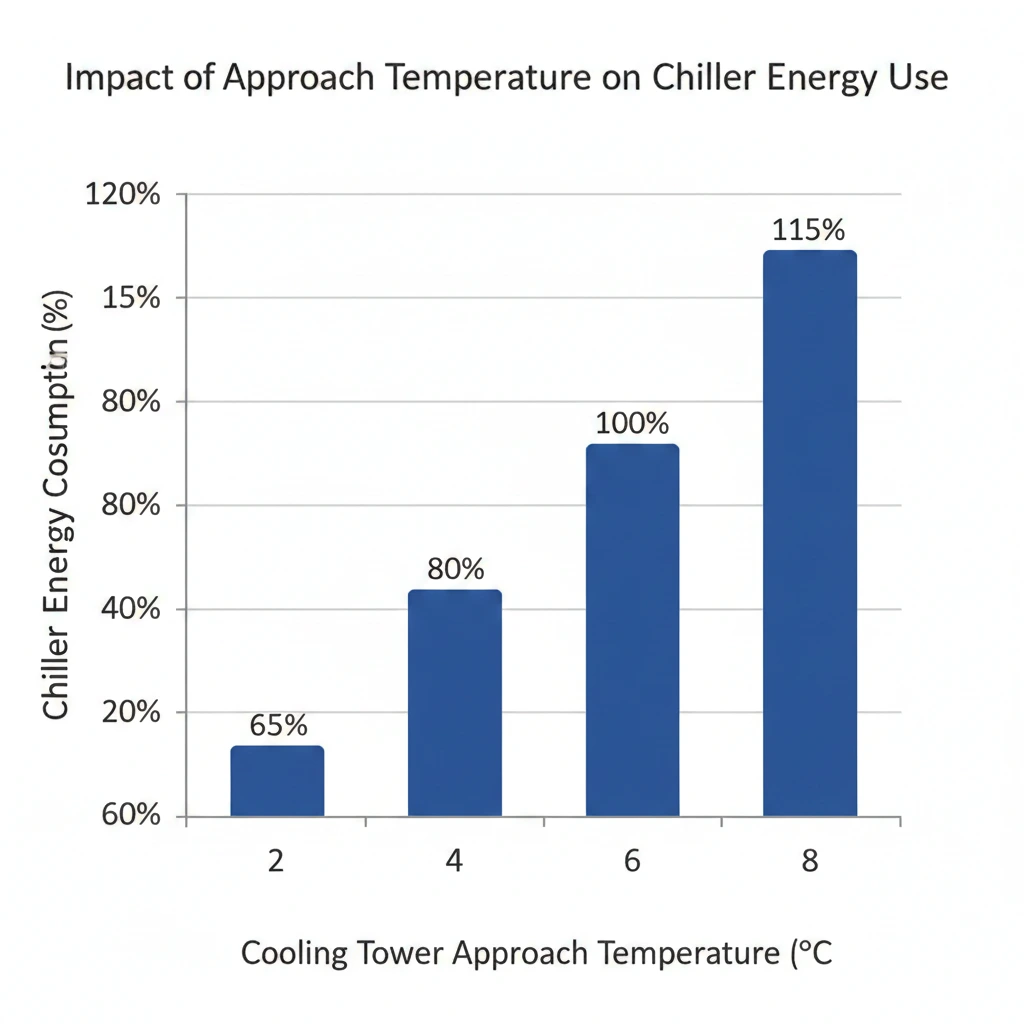

Cooling tower approach temperature directly dictates how hard your chiller works. A smaller approach means colder water enters the chiller. Such a change reduces the physical pressure the compressor must overcome. When the compressor works less, your electricity bills drop. Specifically, every 1°C decrease in water temperature can improve chiller efficiency by about 3%. In the hot, humid climate of India, maintaining a tight approach is the most effective way to reduce total energy consumption.

The Anatomy of the Approach Temperature

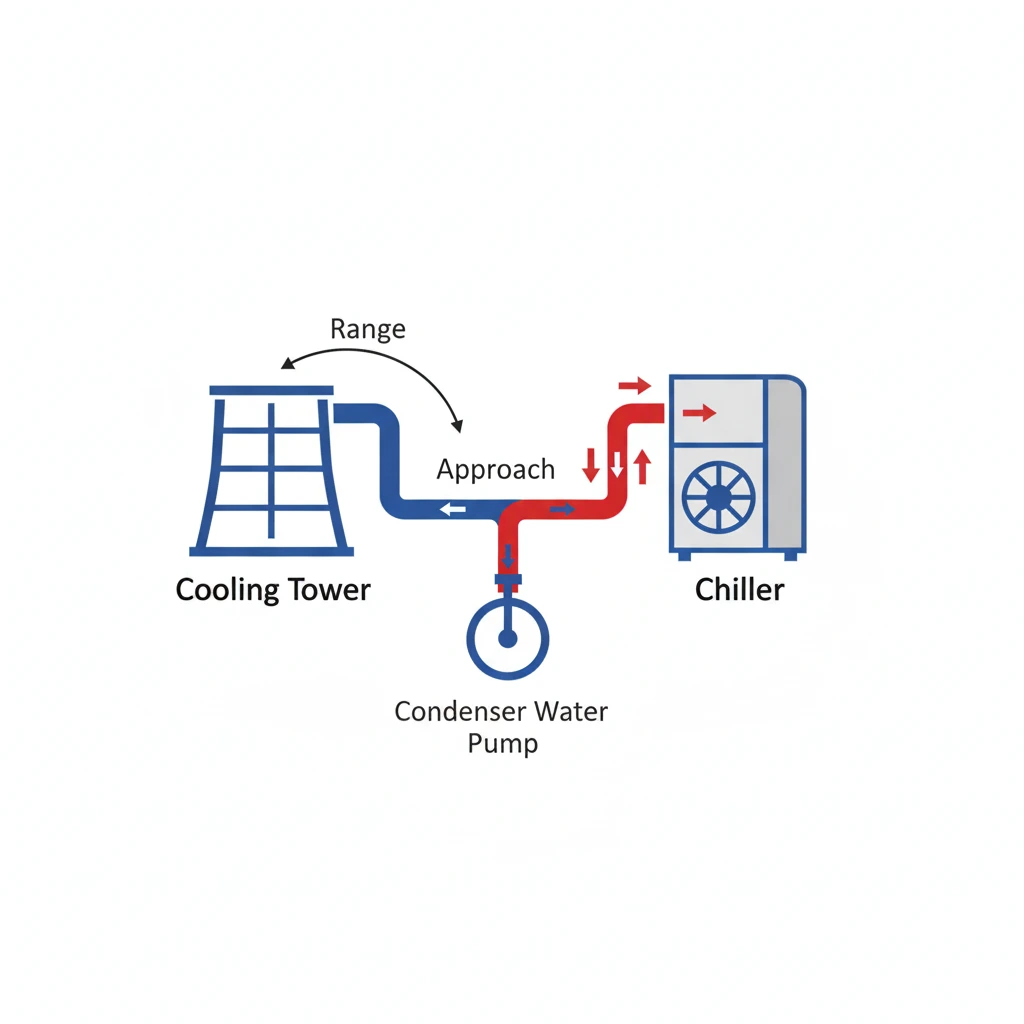

To understand the impact on your overheads, you must first understand the physics of air and water. The approach is the gap between the temperature of the water leaving the tower and the ambient wet‑bulb temperature. The wet‑bulb temperature represents the coldest a surface can get through the process of evaporation.

A cooling tower can never cool water to a temperature lower than the wet‑bulb. If the air is very humid, evaporation slows down. Humidity makes it harder for the tower to shed heat. In many parts of the country, high humidity is a constant challenge. Managing energy consumption in India requires a deep focus on how well your tower “approaches” that theoretical limit.

Why the Chiller Cares About the Tower

The chiller is the heart of a cooling plant, but the cooling tower is the lungs. The chiller removes heat from your building and transfers it to the condenser water. Water then travels to the tower, where it releases heat into the atmosphere.

If the cooling tower has a wide approach, the water returning to the chiller is relatively warm. High‑temperature water entering the condenser increases the “lift” of the compressor. Lift is the difference in pressure between the evaporator and the condenser. When lift increases, the motor requires more amps to move the refrigerant. Increased lift is a primary driver of high energy consumption. By narrowing the approach, you lower the lift and save money immediately.

The Cost of a Wide Approach

When a system is designed poorly or maintained badly, the approach temperature climbs. An approach of 10°C instead of 4°C might seem like a slight discrepancy. But for a 500‑ton chiller, the difference can cost thousands of extra rupees in electricity every day.

Wide approach temperatures often stem from three main issues. First, the tower might be too small for the load. Second, airflow might be restricted. Third, the heat exchange surfaces might be fouled. Each problem forces the entire plant to work harder. The resulting cycle of inefficiency is a major contributor to rising energy consumption in India.

The Mathematical Link: Efficiency and Savings

Engineers use a specific ratio to track performance. A tower with a 2°C approach is significantly more efficient than one with a 5°C approach. While a tighter approach requires a larger tower or more fan power, the savings at the chiller usually outweigh those costs.

| Metric | High Approach (Inefficient) | Low Approach (Efficient) | Impact on Savings |

| Approach temperature | 5°C – 7°C | 2°C – 3°C | Lower is better |

| Chiller workload | High | Low | Reduces wear and tear |

| System power | 1.2 kW/ton | 0.8 kW/ton | ~33% reduction |

| Annual cost | High | Low | Significant ROI |

Table 1: The Efficiency Gap. A direct comparison showing how a lower approach temperature reduces chiller workload and overall energy consumption.

Engineering Solutions for Modern Plants

Achieving tight approach numbers requires precision engineering. Companies like Aad tech specialise in creating high‑performance cooling tower systems tailored to the Indian environment. These designs focus on maximising the fill surface area while minimising the energy consumption of the fan motors. By using crossflow and counterflow technologies optimised for local humidity levels, they help facilities maintain an ideal approach temperature year‑round. High technical expertise is what separates a standard installation from an energy‑efficient powerhouse.

Maintenance: The Battle Against Approach Creep

Even the best‑designed tower will lose efficiency over time. Known as “approach creep,” the process involves minerals in the water sticking to the plastic fills. Scaling creates a layer that acts as an insulator, preventing the water from touching the air.

Regular cleaning is the only way to stop scaling. If you allow scale to build up, your approach temperature will rise by a degree every few months. You might not notice the change when looking at the tower, but you will see it in your energy consumption reports. In some cases, cleaning is not enough.

Explore further: Discover our cooling tower retrofits and when component replacement makes sense to see if your tower needs a deeper upgrade to restore its original approach.

The Role of Water Distribution

Inside the cooling tower, a series of nozzles sprays water over the fills. If nozzles get clogged, parts of the tower stay dry. Blockages reduce the surface area available for cooling. When surface area drops, the approach temperature rises.

A well‑maintained distribution system ensures a uniform “rain” inside the tower. Uniform distribution maximises the contact time between the air and the water. Better contact leads to a tighter approach and lower energy consumption. Plant managers should inspect nozzles monthly to ensure they are not blocked by debris or biological growth.

Airflow and Fan Management

The fan pulls air through the tower. If the fan is not moving enough air, the water cannot cool down. Lack of airflow increases the approach temperature. Many towers in India use fixed‑speed fans. Fixed‑speed units run at 100% power even when the weather is cool.

Installing Variable Frequency Drives (VFDs) allows the fan to slow down when the cooling load is light. VFDs save fan energy. More importantly, they allow for precise control of the approach temperature. By maintaining a constant approach, you provide the chiller with a stable environment. Stability is key to reducing energy consumption in India.

Practical Ways to Reduce Energy Consumption

You can keep your approach temperature in check with simple maintenance. First, ensure the “fills” inside the tower are clean. Limescale acts as an insulator and ruins heat transfer. Second, check fan blades. Proper pitch ensures maximum airflow with minimum motor strain.

Using VFDs on fans also helps. VFDs adjust fan speed based on the actual cooling load. Proper adjustment prevents the system from wasting electricity during cooler nights or winter months. By focusing on minor adjustments, you contribute to a more sustainable level of energy consumption in India.

The Impact of Water Quality

Water quality in India varies greatly by region. In some cities, the water is very “hard,” meaning it contains high levels of calcium and magnesium. Hard water creates scale very quickly. Scale on the cooling tower fills is bad, but scale inside the chiller tubes is a disaster.

A layer of scale just 0.5 mm thick can increase energy use by 10%. Scaling stops heat from passing through to the cooling water. Effective water treatment is not an optional expense. Treatment is an investment that pays for itself by keeping the approach low and reducing overall energy consumption.

Balancing Capital and Operational Costs

When buying a new cooling tower, you face a choice. You can buy a smaller, cheaper tower with a 6°C approach. Alternatively, you can buy a larger, more expensive tower with a 3°C approach.

The cheaper tower saves money today. However, the expensive tower saves money every single day for the next twenty years. Because the chiller uses about 80% of the plant energy, the savings from a lower approach usually cover the extra cost of the tower within two years. Thinking long‑term is the best way to handle energy consumption in India.

Common Obstacles in the Indian Climate

India faces unique challenges like high ambient humidity and hard water. Humidity raises the wet‑bulb temperature, making a low approach harder to reach. Hard water leads to rapid scaling in the tower. Both factors force the system to draw more power. Regular water treatment and smart design are the only ways to effectively combat local issues.

The Importance of Sensor Accuracy

You cannot manage what you do not measure. Many plants rely on old or uncalibrated thermometers. If sensors are off by just 1°C, the data is useless. You might think you have a 4°C approach when it is actually 6°C.

Investing in high‑quality, calibrated sensors is vital. Digital sensors linked to a central monitoring system allow you to see trends. If the approach starts to widen, the system can alert you immediately. A proactive approach prevents high energy consumption from becoming a major financial burden.

Future Trends in Cooling Efficiency

New materials are making it easier to reach lower approach temperatures. Modern “high‑efficiency fills” are designed to create more turbulence in the air and water. Turbulence increases heat transfer without requiring more fan power.

Additionally, smart controllers are becoming more common. Smart systems use weather forecasts to predict wet‑bulb temperatures and adjust tower and chiller settings in advance. Predictive cooling is the next frontier for reducing energy consumption in India.

The Final Verdict: Is Your Approach Temperature Stealing Your Profits?

Monitoring your cooling tower approach is not just a technical chore. Monitoring is a financial strategy. By keeping the temperature difference small, you protect your expensive chillers and slash operational costs. Reducing energy consumption in India starts with minor, measurable improvements in your HVAC infrastructure.

Frequently Asked Questions

Range is the temperature difference between the hot water entering the tower and the cold water leaving it. The approach is the difference between the cold water leaving the tower and the outdoor wet‑bulb temperature.

No. The wet‑bulb temperature is the physical limit for evaporative cooling. A tower can only get close to the wet‑bulb value, never below it, due to the laws of thermodynamics.

An increased approach usually occurs due to fouling. Scale, algae, or debris builds up on the fills. The physical barrier prevents the water and air from exchanging heat efficiently.

Almost always. While a lower approach requires a larger tower and more fan energy, the energy saved by the chiller is usually five to ten times greater than the extra energy used by the fan.

You can monitor the approach daily through your building management system. Sudden changes often signal a mechanical failure, a clogged pump, or a need for immediate chemical cleaning.