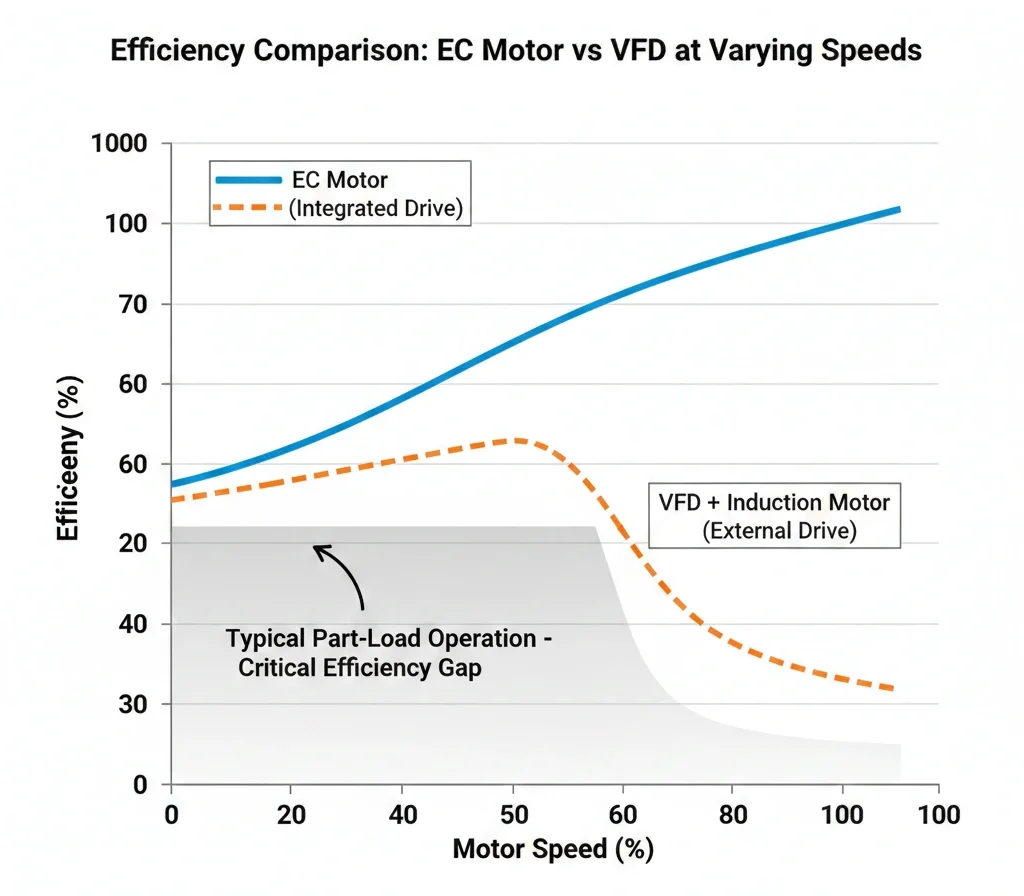

While both change speed, an electronically commutated motor integrates the controller and motor into a single unit, eliminating the energy losses found in external VFD setups. This simple distinction makes a massive difference in your monthly energy bills and the longevity of your equipment.

In the world of industrial ventilation and HVAC, the term “Variable Speed” is often treated as a magic bullet for energy savings. If you slow a fan down, you save money; that is the law of physics. But the way you slow that fan down determines whether you are actually saving as much as the brochures promise. For years, the Variable Frequency Drive (VFD) has been the industry standard, but as energy costs in India continue to rise, many facility managers are realising that the VFD might be the “leaky bucket” of their electrical system.

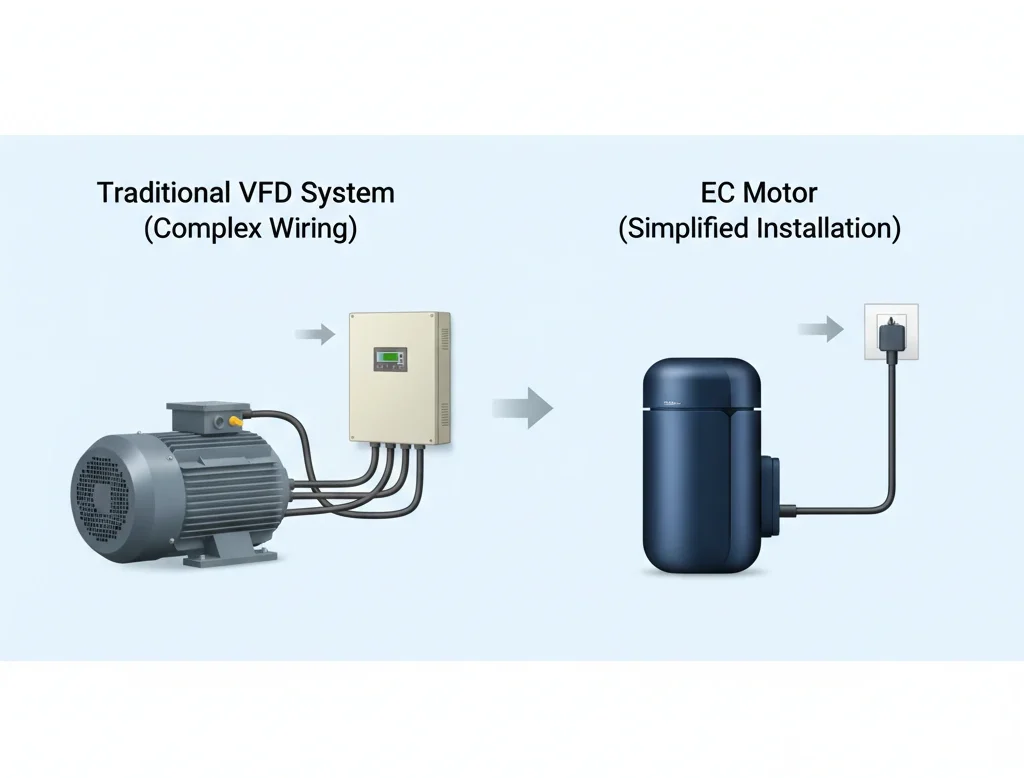

Installation and Complexity: The Indian Plant Reality

The physical footprint of your HVAC system matters more than most people admit until they are standing in a cramped mechanical room. A VFD setup requires:

- The motor itself.

- A wall-mounted VFD box.

- Shielded cabling to prevent interference.

- Often, an external cooling fan is used for the VFD cabinet.

For space-constrained Indian plants, this complexity is a burden. High ambient temperatures in many parts of India also mean that VFDs mounted in poorly ventilated cabinets are prone to premature failure due to overheating.

The EC motor offers a “plug-and-play” alternative. Because everything is contained in a single compact unit, installation is faster and takes up far less space. There is no need for shielded cables between the drive and the motor because the drive is the motor. Aadtech prefers the EC motor for clients who need to maximise their floor space while reducing the number of potential failure points in their electrical cabinet. When you replace a bulky AC motor and its associated VFD with a single electronically commutated motor, you aren’t just saving energy; you are reclaiming physical space.

The Harmonics Issue: Protecting Your Grid

One of the most overlooked “hidden costs” of VFDs is Harmonic Distortion. VFDs are “non-linear loads,” meaning they draw current in pulses rather than a smooth wave. This creates “noise” or electrical harmonics on the grid. This interference can damage sensitive electronics, cause transformers to overheat, and even trigger nuisance tripping of circuit breakers. In a facility with hundreds of motors, this can lead to a massive bill for active harmonic filters to clean up the power.

The internal electronics of an electronically commutated motor handle power much more cleanly. Because the EC motor uses a different commutation method and often includes integrated filtering, it produces significantly lower harmonic distortion. By switching to an electronically commutated motor, you are not just protecting the motor; you are keeping your entire facility’s electrical system healthier and extending the life of other connected equipment.

Tech Specs Compared

| Feature | VFD + Induction Motor | EC Motor |

| Integration | Separate; high wiring | Fully integrated |

| Energy Loss (Low Speed) | High (heat/slippage) | Very low (PM efficiency) |

| Harmonics | High (needs filters) | Low (built-in) |

| Physical Size | Large (cabinet needed) | Compact |

| Maintenance | High (filters/caps) | Low (sealed) |

| Acoustics | Motor whine r | Quiet |

Table 1: Technical Specifications Comparison: Engineering the Future: This detailed comparison highlights why the electronically commutated motor is rapidly becoming the preferred choice for modern HVAC applications in India. While VFDs offer a solution for large-scale retrofits, the EC motor’s superior integration, lack of harmonic noise, and high efficiency at low speeds provide a much faster return on investment for high-precision environments.

The ROI Factor: Is the Higher Upfront Cost Worth It?

It is no secret that an electronically commutated motor usually carries a higher price tag than a standard induction motor. However, looking at the “sticker price” is a mistake. In the industrial sector, the purchase price of a motor typically represents less than 5% of its total lifetime cost; the other 95% is the electricity it consumes.

Because the EC motor operates at IE4 or higher efficiency levels, energy savings are immediate. When you factor in the elimination of VFD purchases, reduced installation labour, and the lack of harmonic filters, the “payback period” in most Indian commercial buildings is between 12 and 24 months. After that period, the savings go directly to your bottom line.

Making the Strategic Switch

Explore further: Understand the science behind EC motors and why EC technology outperforms non-EC solutions.

Selecting an EC motor over a VFD is a strategic move for long-term sustainability. At Aadtech, we have seen firsthand how upgrading older fan systems to electronically commutated motor technology can transform a facility’s energy profile. Stop letting your VFD “leak” energy at low speeds and embrace the integrated efficiency of EC.

Frequently Asked Questions

An electronically commutated motor is generally better for fans and pumps under 7.5kW (roughly 10 HP) due to its higher efficiency and smaller size. VFDs remain a practical choice for retrofitting very large, existing industrial motors (e.g., 50 kW+) where total replacement is not yet financially feasible.

Yes. Upgrading to EC motor technology is a common way to modernise HVAC systems in hotels, hospitals, and offices. Aadtech specialises in these upgrades to help facilities slash maintenance costs and improve reliability.

The upfront cost is often higher, but the Return on Investment (ROI) is rapid. Between the energy savings at part-load and the lack of external drive maintenance, most units pay for themselves very quickly through reduced operational expenditure (OPEX).

Most EC motor models accept standard 0-10V or Modbus signals, making them perfectly compatible with your current Building Management System. You get better data and better control without changing your software.

With no carbon brushes to wear out and operating temperatures lower than those of induction motors, these motors often last over 10 years, even in demanding Indian climates.

No. The beauty of an electronically commutated motor is that the controller is part of the motor itself. You simply provide power and a speed signal.